- Theindustrialpartfinder@gmail.com

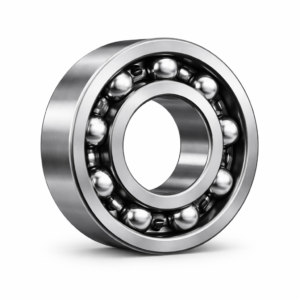

6206-2RS Deep Groove Ball Bearing | OEM Replacement Bearing

6206-2RS Deep Groove Ball Bearing (2RS (rubber seals)). OEM replacement bearing for common industrial and general-purpose applications. Submit an RFQ for fast sourcing.

Want Request a Quote for this Part?

Drop a part number, name, or keyword – we’ll hand the rest.

Save time, Stop pulling your hair out, Let us find it for you.

6206-2RS Deep Groove Ball Bearing – OEM Replacement

Overview

The 6206-2RS deep groove ball bearing is a best-seller for 30 mm shafts in industrial motors and drives. It delivers smooth rotation, low friction, and solid radial load capacity with sealed protection for longer service life in real-world plant conditions.

Applications

Common applications include industrial electric motors, pump assemblies, fans, gear reducers, and rotating idlers. The double-sealed 2RS design helps keep contaminants out and grease in—especially useful in dusty production floors and general manufacturing.

Compatible Machines

You’ll typically see 6206 bearings in medium-size motor frames, pump coupling ends, blower shafts, and belt-driven equipment. They are also used in a wide range of aftermarket repair kits because of their standard sizing and availability.

Technical Specifications

- Bore (ID): 30 mm

- Outside Diameter (OD): 62 mm

- Width: 16 mm

- Sealing: 2RS rubber seals (double sealed)

- Typical material: chrome steel (52100) or equivalent

- Lubrication: pre-greased for general-purpose duty

Cross References

Cross references include 6206, 6206-2RS, 6206-RS, 6206-ZZ, and multiple brand suffixes. If your application requires extra clearance (C3) or high-speed grease, include that in your RFQ so the replacement matches operating conditions.

Replacement Information

Confirm the code and measurements (30×62×16 mm). Inspect for heat discoloration, vibration damage, or housing wear. Use proper installation: heat the bearing or use a press on the correct ring. If the environment is cleaner and speed is higher, a shielded ZZ version may be preferred.

Why Source With Us

We can supply OEM replacement 6206 bearings with configurable seals, shields, clearances, and brand preferences. Send your RFQ and we’ll quote availability and provide alternates if you need an immediate substitute.

Internal Links

Quick FAQ

What does the suffix mean? Common suffixes include ZZ (metal shields) and 2RS (rubber seals). Seals help retain grease and exclude contamination.

How do I confirm fit? Match the bearing designation, bore size, OD, and width. If your old bearing has an extra internal clearance suffix (like C3), keep that specification.

Can I upgrade quality? Yes—use premium grades for higher speeds, higher temperatures, or continuous-duty service.

Related Products

Related products

-

6009 Deep Groove Ball Bearing | OEM Replacement

Read more -

6305 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6307 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6309 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6306 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6300 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6301 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6209 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6206 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6207 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6205 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6008 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6201 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6007 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6006 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6001 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

6004 Deep Groove Ball Bearing | OEM Replacement Bearing

Read more -

608-2RS Deep Groove Ball Bearing | OEM Replacement Bearing

Read moreProduct successfully added to the Quote List

-

6305-2RS Deep Groove Ball Bearing | OEM Replacement Bearing

Read moreProduct successfully added to the Quote List

-

30205 Tapered Roller Bearing | OEM Replacement Bearing

Read moreProduct successfully added to the Quote List

FAQ

1. How do I find an industrial replacement part without the original part number?

You can identify a replacement industrial part by matching key specifications such as dimensions, mounting style, material, load capacity, voltage, speed rating, and application. Many industrial components can be sourced by size and performance specifications even if the original part number is unknown. Providing measurements, photos, or equipment model information can help ensure accurate identification and compatibility.

2. Can I identify an industrial part using only dimensions?

Yes. Many industrial components — including bearings, seals, belts, motors, and fasteners — can be identified using inside diameter, outside diameter, width, thread size, or mounting pattern. Matching exact dimensions is one of the most reliable methods for finding equivalent or replacement parts when a part number is missing or unreadable.

3. How do I identify an industrial part from a machine model number?

Machine model numbers can often be used to locate OEM parts diagrams, exploded views, and manufacturer replacement lists. These references help identify compatible components originally installed in the equipment. Matching parts by machine model ensures correct fit, performance, and operational reliability.

4. How do I cross reference an OEM part number to another brand?

OEM part numbers can be cross referenced using manufacturer interchange guides, engineering specifications, or industrial databases. Matching dimensions, tolerances, materials, and performance ratings ensures the alternative component functions the same as the original.

5. How do I confirm if two industrial parts are interchangeable?

To confirm interchangeability, compare critical specifications such as dimensions, mounting configuration, operating capacity, material composition, and tolerance class. If these parameters match, the components are typically interchangeable across manufacturers.

6. What happens if I install the wrong industrial replacement part?

Installing an incompatible part can lead to premature wear, mechanical failure, reduced efficiency, overheating, vibration, or equipment damage. Always verify specifications and compatibility before installation to maintain performance and safety.

7. Are metric and imperial industrial parts interchangeable?

Metric and imperial components may appear similar but often differ slightly in size and tolerance. Even small measurement differences can affect fit and performance. Always verify exact measurements before substituting between measurement systems.

8. What are tolerance ratings in industrial components?

Tolerance ratings define the allowable variation in size, alignment, or performance. Tight tolerances improve precision, reduce vibration, and extend equipment lifespan.